CLIENT INSPECTION OF A REFURBISHED EXPANSION JOINT

Steel Plant

Steel Plant

Europe

Europe

EJMA

EJMA

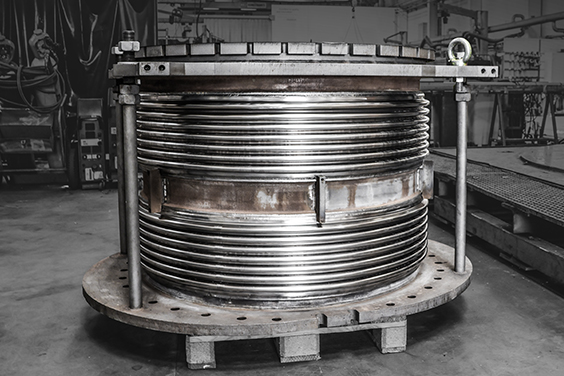

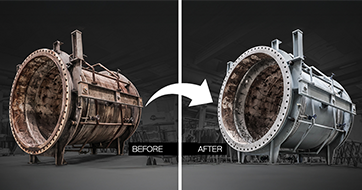

Belman refurbished a damaged Expansion Joint for a steel plant in Europe. The Expansion Joint was installed at the blast furnace. This refurbishment helped the steel plant select a greener solution rather than buying a completely new Expansion Joint. The client came to Belman to conduct a final inspection before dispatching the renovated Expansion Joint to the plant for reinstallation. Belman always warmly welcomes both clients and third-party inspectors at our facilities.

CLIENT ISSUE

The client contacted Belman’s local partner to explore the possibility of refurbishing a damaged Expansion Joint installed at its blast furnace rather than purchasing a new one. Belman had previously refurbished a similar Expansion Joint for them in 2017. As the steel plant was now facing damage to another Expansion Joint of the same design, the client wanted to assess refurbishment options. To evaluate feasibility, Belman was asked to carry out a thorough inspection to define the condition of the Expansion Joint parts as well as define the scope of work. Based on this, the client wanted to compare costs and benchmark refurbishment against alternative solutions such as buying a completely new unit. As agreed, the client dismounted the Expansion Joint and sent it to Belman’s facilities for detailed inspection and evaluation.

Steel plants are increasingly shifting toward greener practices Expansion Joint design

Steel plants around the world are increasingly moving towards greener, more sustainable operations in response to growing environmental concerns and regulatory pressures. A shift from traditional steel production methods to the production of low carbon “green steel” using cleaner energy and innovative methods resulting in steel produced with significantly reduced carbon emissions. Many steel producers are also rethinking their approach to equipment maintenance and component lifecycle management. Rather than opting for a full replacement of worn out or damaged components, there is a growing emphasis on repair, refurbishment and reuse. This extends equipment life, cuts waste and lowers the carbon footprint, thereby supporting the industry’s transition. For that reason, refurbishment of the Expansion Joints was a very attractive solution for the client.

BELMAN SOLUTION – Expansion Joint refurbishment

It was agreed with the client that the initial scope of the Expansion Joint refurbishment process was:

(1) Inspection & evaluation:

1. Cleaning the Expansion Joint

2. Marking position/orientation of both flanges

3. Disassembly

4. Sand blasting of all components (excl. Bellows and inner sleeves)

5. Measuring thickness pipe spools: inlet Expansion Joint, middle pipe and outlet

6. Checking the straightness of the sealing surface of both flanges

7. Sending an inspection report for points 1-6

(2) Hold point: proceed after approval from the client

(3) If approved: refurbishment

Upon the Expansion Joint’s arrival at Belman, a thorough inspection of the Expansion Joint was conducted. The parts were sandblasted and cleaned to remove dust and corrosion, to see their actual condition and confirm that they could be reused. At the same time, they were prepared for priming in the event of reuse. An inspection report was completed and sent to the client. In the inspection report, Belman suggested replacing the following parts and then reusing the rest:

• Two new Incoloy 825 Bellows

• Two new inner sleeves

• Partially new pipe end at inlet

• New ceramic gasket between inner sleeves and pipe spools

• Apply new coating system (primer)

After client review and evaluation of the quotation, it was decided to proceed according to the above. This was a hold point, and the refurbishment could not be initiated before final approval of the procedure and pricing.

The original top flange had a special spiral groove. After sandblasting, the special spiral groove was gone, and the client needed a new one made to ensure an effective seal. This was also added to the process.

Client inspection

The client requested a final inspection of the refurbished Expansion Joint. Belman fully supports such involvement, as it fosters transparency, builds trust and ensures alignment with quality expectations. This open approach to inspection reflects Belman’s commitment to quality, compliance and strong long-term client partnerships.

Performing the final inspection allowed the client to verify that the Expansion Joint met all performance, safety and technical standards as well as to verify that materials, workmanship and test procedures aligned with the agreed specifications and relevant standards. The client sent a very experienced inspector and, as always, Belman made sure everything was ready for him, including the full Manufacturing Data Book (MDB). Among other things, the inspector checked the following:

• Material certificates

• Welding documentation, NDT etc.

• Measurements and tolerances of the Expansion Joint

• That the refurbished Expansion Joint matches the old drawings

As agreed, the hydrostatic pressure test was performed beforehand without the inner sleeves, sealing and insulation. The inner sleeves were mounted after testing without the use of additional sealing rings – this is consistent with previous repairs carried out by Belman. PED/CE requirements were not applicable for this scope, and the process followed the same procedure used in an earlier refurbishment in 2017 (as agreed with the client).

Belman – experts in Expansion Joint refurbishments for steel plants

Belman has established itself as a trusted partner for clients (incl. steel plants) seeking sustainable and cost-effective solutions through the refurbishment of Expansion Joints. With over 30 years of experience in designing and manufacturing Expansion Joints, Belman specialises in evaluating and refurbishing Expansion Joints, offering significant cost savings and environmental benefits compared to full replacements. Our experience ensures accurate assessments of which parts can be repaired and reused and which require replacement. This strategy not only conserves resources but also aligns with the steel industry’s move towards greener practices. In this way Belman can help steel plants move in that direction. Belman refurbishes both our own Expansion Joints and those from other manufacturers, delivering high-quality results regardless of origin.

DESIGN FEATURES

Design parameters of the refurbished Expansion Joint:

Type: Special Double Bellow Expansion Joint • Quantity: 1 pc. • Dimensions: DN 1200 • Installation length: 1000 mm • Medium: Blast furnace gas • Design pressure: 3 barg • Design temperature: 300°C • AX: +/-40 mm • LA: +/-9 mm • New Bellows: 2.4858 (Incoloy 825) • Inner sleeves: 1.4541 (16Mo3) • Pipe end: 1.0425 • Design code: EJMA

CLIENT BENEFIT

- Less scrap, as only worn-out parts were replaced

- Cost savings, as only worn-out parts were replaced

- Assistance from a manufacturer experienced in cost-efficient Expansion Joint refurbishment

- No compromise on product quality and quality assurance

- A refurbished Expansion Joint that performs as well as a new one

- Supports the steel plant’s move towards greener solutions

RELATED INFORMATION

TECHNICAL information

- More information about the refurbishment of Expansion Joints

- More information about manufacture, welding and testing at Belman

REFERENCES

Thyssenkrupp • Severstal • TATA • ArcelorMittal • SSI (CORUS) • SSAB • Salzgitter • NLMK Group • Nornickel • Ruukki • AET Technologies • ISD Dunaferr • Gerdau • Salzgitter Flachstahl GmbH • TRIMET • Voestalpine • Steel dynamics • Usiminas • Hüttenwerke Krupp Mannesmann (HKM) • Al Ezz Dekheila • FENI • Steel – EZDK • Evraz • Paul Wurth • Siemens VAI • Corus • Aurubis • SMS Group • Kalugin •

RELATED CASE STORIES

Renovation of DN 2600

Expansion Joint

Belman assisted a steel plant in renovating one of its DN 2600 Expansion Joints (not originally produced by Belman). This renovation provided significant cost savings and a positive environmental impact.

COST SAVINGS ACHIEVED BY

REPAIRING BELLOWS

Belman ensured an oil refinery significant cost savings and downtime reduction by repairing its Corner Relief Expansion Joint. This included replacement of the Bellows, inner sleeves and the tie rods.

REFURBISHMENT SOLUTION FOR A DISTRICT HEATING PIPELINE

For a district heating pipeline owner, Belman analysed and found that the cost of refurbishment was 49% cheaper than buying completely new Expansion Joints. Only worn-out bellows were scrapped; the rest was reused.